The reason why ENVE has become one of the benchmarks at the level of carbon components, is, without a doubt, for its high-quality products, design, and performance. Another great peculiarity that differentiates them from the rest is that from the beginning they decided to bet on local production in the United States, more specifically in the state of Utah. This factor has been key in the development of the brand and allowed them to have precise control of every part of the production process, from product development, quality tests, optimization, manufacturing, and marketing.

Just a few weeks ago we saw how the North American brand hit the table and knocked out its competitors with the presentation of its own bicycle, the ENVE Custom Road Bike. A milestone that they envisioned since the creation of the brand in 2007, but that they did not want to tackle until they had the necessary knowledge and experience in developing and manufacturing wheels and components of the highest quality and performance.

We had the opportunity to speak with Jake Pantone, Vice President of Product and Head of Consumer Experience at ENVE, who gave us first-hand insight into the details behind this great project.

Development of the idea

In the big brands, they design a bicycle model and define a size catalog based on that geometry, but in ENVE they manufacture 100% of their products. Thus, the access to the design and development tools allowed them to visualize the possibility of creating something totally personalized. At first, they doubted its viability, but their bet to launch something different made them pull forward. Thus, at the end of 2018, they finally signed a project to build a custom carbon bike frame.

“We work with custom frame builders that offer a very high-touch and personalized experience, but those bikes lack is technological benefits like aerodynamics, integrated features, or carbon construction. This is why, from ENVE, we wanted to offer complete customization in carbon.”

Most of ENVE’s customers and products revolve around road cycling, so when designing the frame, they decided to invest in that direction.

The company has been building wheelsets to fit bikes from other companies for years, so they knew what features on a frame and aerodynamics are important. Their goal was not to make the most aero bike, but the most versatile one, providing the best and unique bike with excellent performance in all kinds of rides.

The process behind the Custom bike

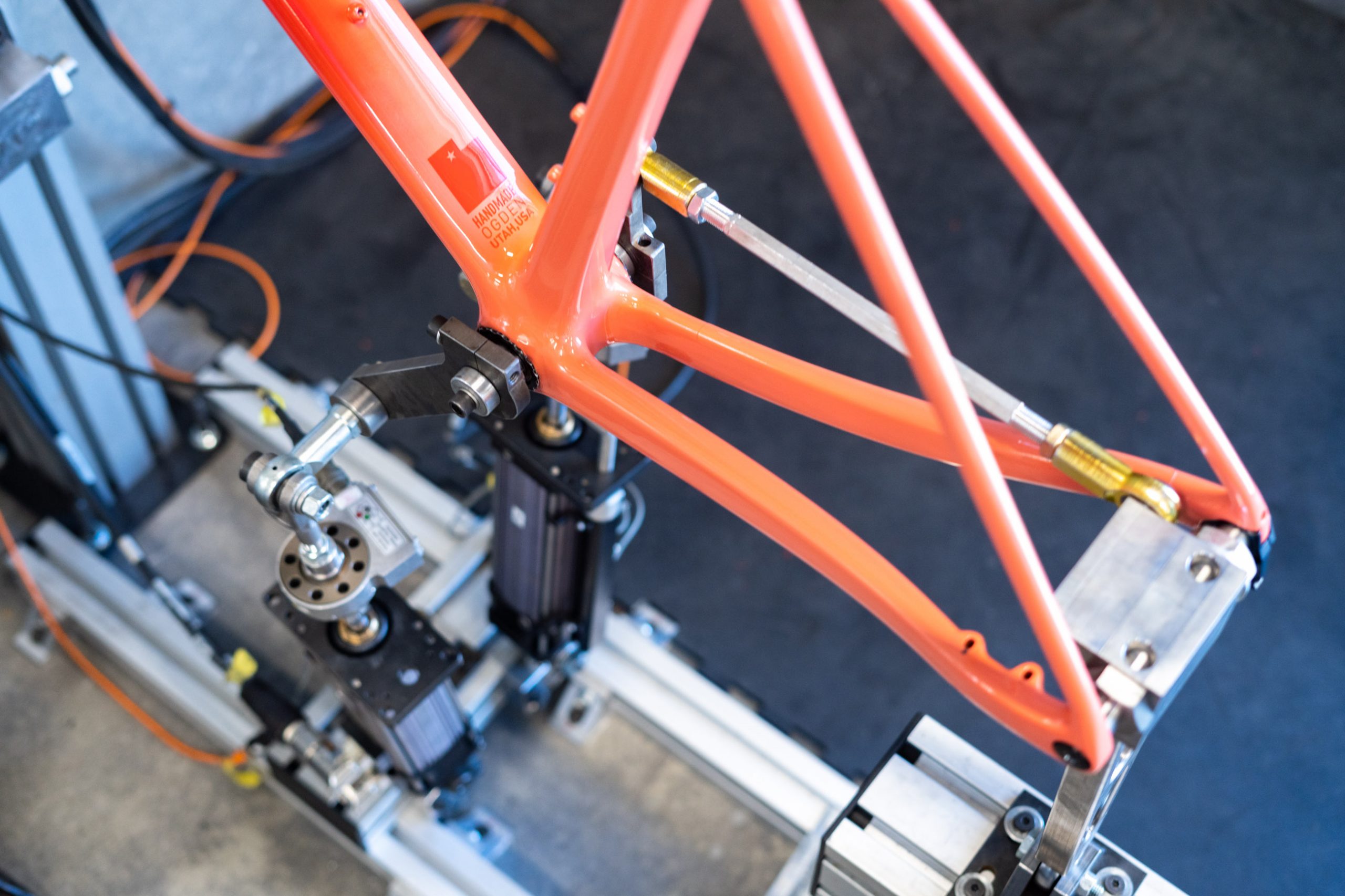

As of the beginning of 2019 the process to shape the bike started. The first efforts focused on laying out the frame and learning how to join the tubes together to get the first ridable prototype, which Jake Pantone received by the end of the same year. From that moment, they started to work in the wind tunnel, figuring out where to invest in the design.

The first half of 2020 was an iteration and improvement process of the first prototype, testing different tubes, laminates, and construction of the handlebars and seat tubes. Nonetheless, their previous experience with the material resulted really beneficial in order to achieve what they were aiming for in a short period of time.

“It was starting from scratch but not completely from zero. In the end, it took two years to take the bike from concept to market.”

It is interesting to note that the bike was designed only for electronic shifting and brake hoses that are all hidden into the structure. There was a lot of work to fit everything in the headset and the frame, but despite that the design process started almost three years ago, the market and component companies, such as Sram or Shimano, have worked in their favor.

The bicycle

The need to offer custom products in the cycling market is a fact, therefore, large brands such as Trek with its Project One have made some attempts to get closer. However, at ENVE, they had all the tools and knowledge to offer complete customization, from paint and components to custom geometry for each customer.

“The main challenge is to decide the perfect fit for the customer without having him come to the factory. We have to rely heavily on bike fitters and the riding experience of the client.”

We all have a favorite bike, with a specific reach and stack that work well for us and make the bike react as we expect when we ride it. In this way, depending on your preferences, a bike fit, and your measurements, these numbers can be adapted to your ideal frame size, saddle height, and handlebar size and position so that the bicycle is manufactured by and for you.

“The thing is that there are not many bikes to try, so the customers buy them and then ride them, but the feedback has been very positive. The feedback will continue to grow as we build more bikes and with this, we will also make some improvements.”

They offer two different geometry styles that stay within a certain range: one is shorter in terms of wheelbase to offer high-performance, and the other is a longer and more comfortable version designed for all-road (not meaning it is a gravel bike). All bicycle measurements are customizable, but they will always be accompanied by advice from the brand itself to always achieve an optimal and balanced result.

The future of the Custom adventure

This bike is the first step as they are coming with a halo product into the market that is directly sold from them to the customers. In ENVE headquarters there are many athletes, from MTB to triathlon, so they are envisioning designing frames for other disciplines, probably a great candidate for the future will be the ‘ENVE Custom Gravel Bike’.

Also, they are considering supplying a more affordable bike with the all benefits of ENVE products. For that, there are several options on the table like doing some stock geometries instead of fully custom bikes.

For now, they are producing one bicycle per day as they have just started and do not have a high production capacity yet. They rely heavily on wheel and component manufacturing so they are seeing how the market reacts to their bike, and if the frame build is unsuccessful they can always go back to basics. This is undoubtedly one of the reasons why, initially, the launch of the bike is only available in North America. If everything goes according to plan, in a matter of months they will be in a position to produce for the rest of the world.

“We want to make sure we are operational and excellent before starting shipping bikes far. We expect that years from now people will recognize ENVE as much as we are recognized as a wheel and component manufacturer. We want more people to experience our frames and the technology we can bring to the market.”

Even if some pro-Tour cycling teams ride their wheels and components, the limitation in production capabilities is a constrain for bringing ENVE frames to the cycling peloton. However, if the project keeps on growing we might see some in the future.

A special collaboration with Chris King

One of the great allies that ENVE has had throughout these years has been the precision components brand Chris King, for the most part with the assembly of wheels. The historic and renowned Portland brand has been commissioned to complete the assembly of an endless number of ENVE wheels with their highest quality hubs and their unmistakable sound (angry-bee sound, as the brand defines it).

On this occasion, they have returned to work side by side. From ENVE, they had the idea of integrating the cables and hoses through the headset in a different way and thanks to the help of Chris King, they managed to develop it. What is interesting about the system is that it allows running a traditional steer tube and that all it requires is a larger bearing on the top. However, the routing is clean and it does not require disconnecting anything, so it is as user-friendly as possible. The spacers split and you can add and remove spacers very easily or trimming the hoses without disassembling everything.

“Of course, it is a little bit complicated when you install the headset for the first time, but it is just painful once and you then don’t have to worry anymore.”