Rubén never misses an opportunity to continue learning and improving as a professional. We’ve seen him visit the workshops of Italy’s most legendary artisans, participate in events specifically for frame builders, and cross the Atlantic on several occasions to present his latest projects wherever he’s invited. Without a doubt, “Rizzo Cycles” is a restless, motivated individual eager to keep growing in his career as a frame builder. In this article, he explains his latest experience in the United States, where, after once again participating in the renowned Grodeo event organized by the American brand ENVE, he decided to spend a few weeks visiting some of the country’s most relevant workshops.

After this year’s Grodeo wrapped up, my real journey began: a 3-week road trip around the American Southwest visiting the builders who shaped titanium’s past and continue to define its future.

The trip began in Steamboat Springs—home to Moots and Bingham Built—and expanded into a tour of workshops across the region. I witnessed, up close, different ways to build bikes as well as different ways to build a life around them.

Moots: Four Decades in Titanium

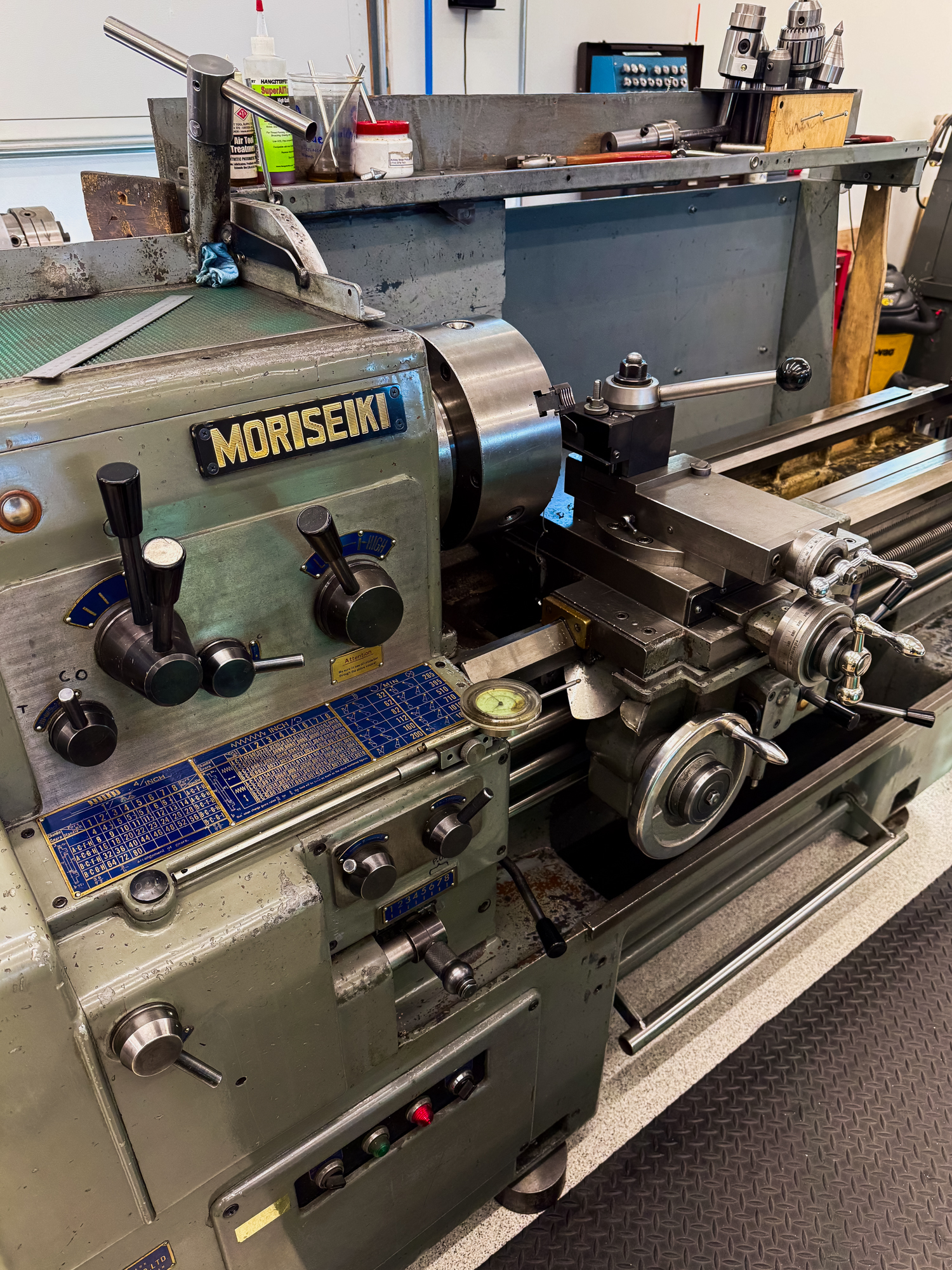

Founded in 1981 by Kent Eriksen, Moots has been refining titanium for 44 years. Kent left in 2005, but his influence lives on in the custom-built fixtures, one-off machines, and processes that he invented on-site and are still in use today.

Moots now produces more than a thousand frames per year — far from my own scale — yet the craftsmanship hasn’t disappeared into the numbers. Thanks to a crew of young builders keeping the tradition alive and Nate Bradley at the helm, the floor buzzes with energy and life.

Moots isn’t just a company. It’s an institution. I observed how they manage workflow and materials for such high volumes. I could never fully grasp how the big guys handled tricky/meticulous tasks, like drilling the tubes for internal routing with a dedicated mini mill. Seeing their custom tools, jigs, or machines solve these complicated problems was illuminating. Moot: a reminder of how far titanium can scale without losing its soul.

Brad Bingham: Precision, Patience, Perfection

If Moots represents scale, Brad Bingham represents focus. Brad began at Moots when he was 19, continued working with Kent at Eriksen Cycles, and eventually took over after Kent retired. Today, he’s earned multiple Best TIG-Welded Frame awards and a reputation as one of the world’s most precise titanium builders.

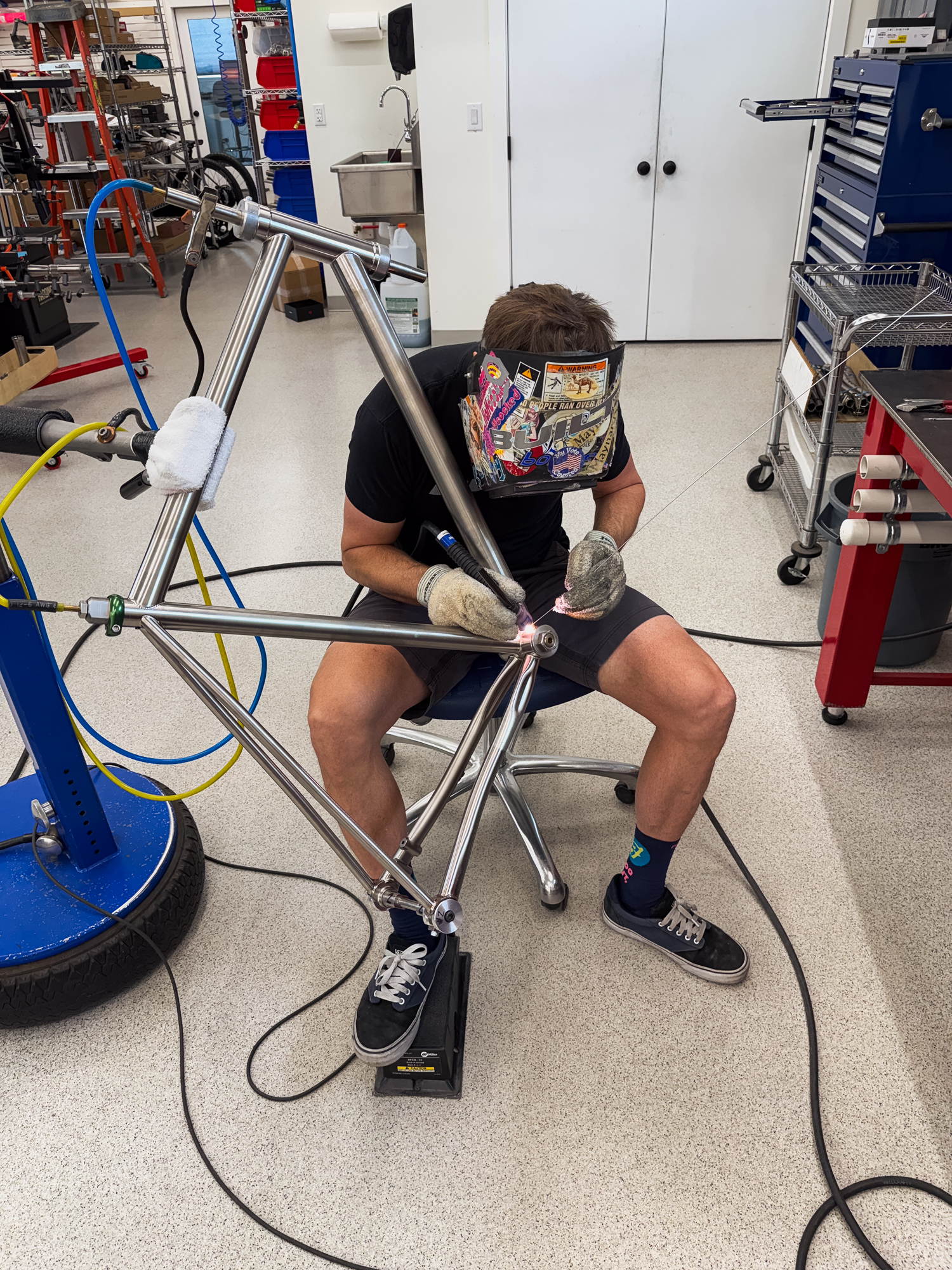

I spent four days in his shop, building a frame from start to finish. Those days reshaped how I see the process.

I learned that time is not wasted but essential—perfection isn’t fast. His workshop is a living archive of thirty years of machines and custom jigs, each tool refining and defining his workflow. Watching him weld in real time gave me insights that no photo ever could.

The finishing work was a lesson in itself — from sandblasting, reaming, and taking care of every detail that titanium in its unfriendly nature demands. Beyond just building, Brad’s connection with his clients made an impression on me. He is as committed to their experience as he is to the precision of his welds. Another takeaway from visiting Brad was the power of the people around him. Between his wife, Hanna, and his assistant, Jon, I could feel the strength of his support system.

If Moots is the cathedral of titanium, Brad’s shop is the chapel: quiet, precise, and personal.

Workshop Wonders: Lessons from other builders

From Steamboat, I continued traveling to the Front Range. Each stop revealed another person, another place, another perspective on bikes, another artistry, and another way of building a life around both.

At Mosaic, I observed production efficiency sharpened by the addition of in-house paint. Additionally, we rode the flowiest trail of my entire trip at Hall Ranch in Lyons. At Reeb, I stepped into a brewery-bike-shop hybrid, turning out mountain bikes with character. Oddity revealed a countryside dream shop — compact, organized, and brimming with tube-bending knowledge.

I also met Significant Other, a highly skilled welder whose work often goes unnoticed as they build frames for other brands behind the scenes. At Da Vinci Designs, I observed three decades of tandem expertise distilled into a process that produces up to three frames a week, with precision from veteran Eric Baar.

In Durango, Josh Ogle showed me the design brain behind many of Firefly’s small CNC parts, blending decades of framebuilding with cutting-edge modeling. Josh also showed me the joy of riding the Hermosa Creek trail. At Sanitas (formerly Dean), the conversations revolved around sourcing titanium and developing full-suspension MTBs.

My final stop, Blaze in Moab, was an unexpected highlight—a workshop where self-taught CNC mastery proved that the hardest skills can be learned by just going for it. Outside of the shop, Ian took me on some of the most memorable rides of my life. “Let’s ride, Captain Ahab,” he said. “We will reach the top for a perfect sunset.” He was right. It was magical. I was overwhelmed with gratitude. I would not have witnessed that amazing sunset if it weren’t for Ian and the frame building community. Things went a bit downhill from there as darkness snuck up on us and we had to descend without any lights–a bit sketchy, but unforgettable nonetheless.

Aside from the dreamy landscapes, all of the trails I rode in the Southwest left an impression on me regarding their maintenance. From signage to berms and even one-way trails, everything is designed to give you an exceptional, smooth riding experience. Brad and Nate told me all about the trail building and care that goes into the trails, and I was completely blown away. Compared to Spain, the MTB infrastructure I enjoyed is industry-leading.

Carrying It Forward

What struck me most wasn’t the knowledge itself, but the way it was shared. Some builders didn’t understand why I was visiting — they thought I was already “above” them. But framebuilding doesn’t work like that. There’s no hierarchy here, only different paths.

Each workshop offered something unique: a tool, a trick, a philosophy. From Moots’ production scale to Oddity’s countryside creativity, these visits showed me that the real craft lies not only in building frames, but in building connections and community around bicycles.

One weld. One detail. One conversation at a time.