In a world where impulse buying and instant gratification are part of our daily lives, it’s easy to ignore the processes that go into producing the products we consume on a daily basis. This is precisely what we’d like to change through our set of articles called “Visiting Industry Players”. On our way back from their facilities, we took the opportunity to recount our latest episode in this series, this time featuring Hutchinson Cycling.

In a mere 24 hours, we traveled to Montargis, a small town south of Paris, home to one of the Hutchinson Group’s most important facilities. The city, known for its canals that crisscross much of its territory, houses a major complex where the group manufactures part of its product range, including its cycling division. Its global research center, encompassing all branches of the company, is also located there.

History of the brand

Founded in 1853 by Hiram Hutchinson and with over 40,000 employees worldwide, Hutchinson specializes in the manufacturing of rubber products and operates in various business areas, including the automotive, aerospace, rail, and cycling industries, among others.

Although the cycling products division represents a small share of the group’s total production, we consider the brand has been a reference in the history of cycling. And that’s not all. Thanks to innovation, experience, and extensive knowledge, it remains one of the leading brands in product development in the sector today.

Among the most significant milestones in Hutchinson Cycling’s history is the introduction of Kevlar in 1988, which pioneered its use in tire manufacturing to increase puncture resistance. Another major breakthrough that significantly changed cycling was the 1999 invention of the UST (Universal System Tubeless), developed in collaboration with other partners. A few years later, in 2006, Hutchinson expanded its portfolio with the first tubeless road tire and the first tubeless-ready mountain bike tire. As you can see, what we now consider essential in our daily lives as cyclists is primarily thanks to this company.

Despite its long history, with the arrival of gravel bikes, the brand has taken a significant step forward in terms of presence and visibility, successfully positioning itself against its competitors. In recent years, they have worked hard to improve communication and convey the brand’s values. The road ahead is still long and complex, with fierce competition, but we are confident that the quality of the products they will offer will soon bring them the recognition the brand deserves.

“Made in France” stamp

We were fascinated by the opportunity to learn about the manufacturing process behind products we know and use ourselves. It’s like experiencing an episode of the famous TV show “How It’s Made” firsthand, but with the bonus of being able to interact and ask questions.

The Montargis factory produces around 3,000 tires a day, totaling 1,000,000 units annually. While these figures may seem impressive at first glance, when compared with other players in the industry, it’s considered a medium-sized production facility. They are responsible for everything related to Hutchinson’s high-end products, as well as the research and development of prototypes and new products. For entry-level products, manufacturing is outsourced to the brand’s factories located in Asia.

Knowing everything that goes into developing a tire is nearly impossible unless you’re an expert in the field. It all begins in the laboratory, where they focus on formulating the different compounds needed to produce the desired rubber compound for each product. A single tire can contain up to three different compounds.

Another key factor is the Threads Per Inch (TPI). A higher TPI means greater lightness, flexibility, and speed, but also less durability. However, if we lowered the TPI, we would obtain a heavier, more robust tire with better grip and greater puncture resistance.

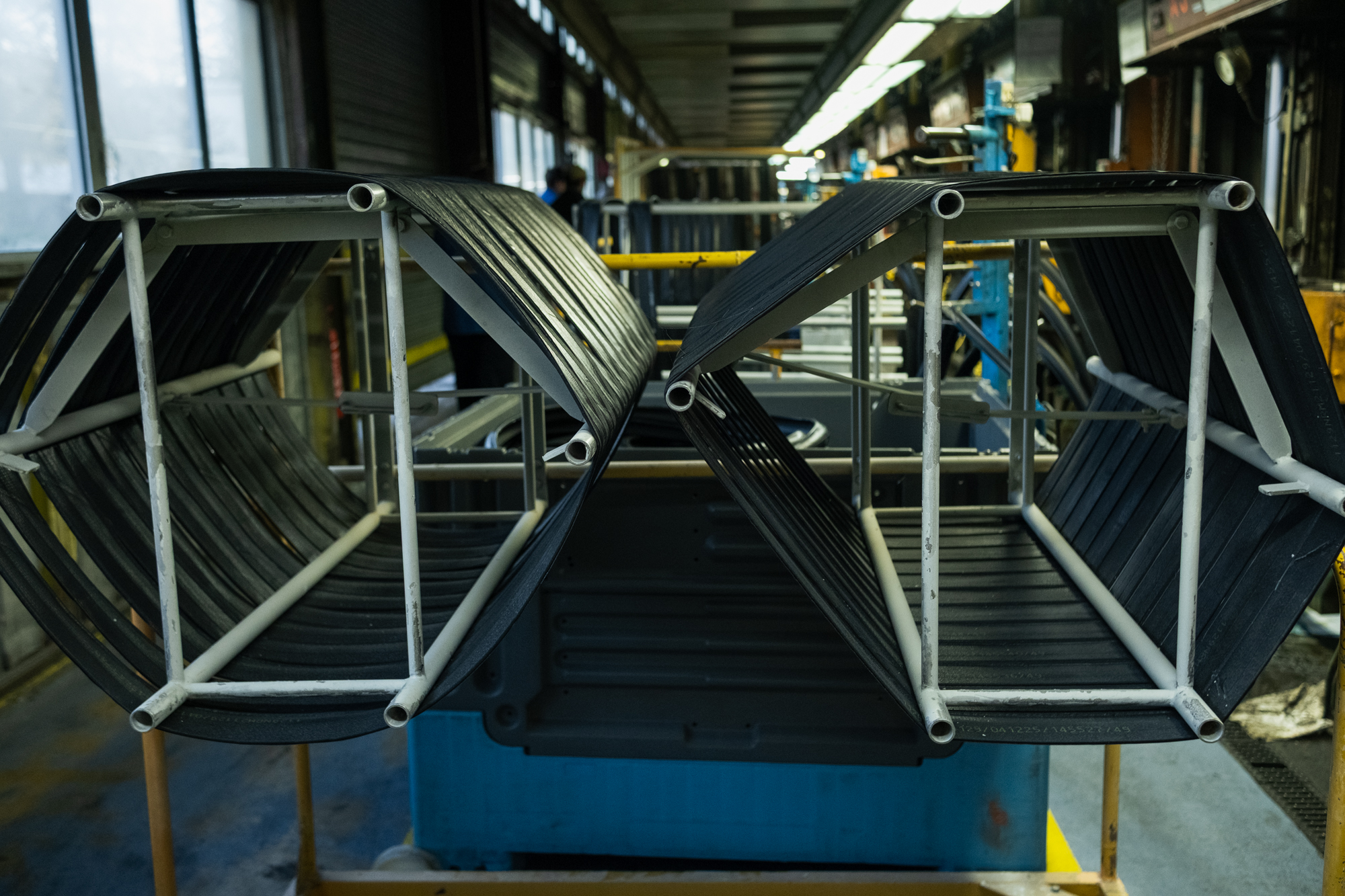

Step by step, the tire takes shape in the different manufacturing phases: from the preparation of the materials and their assembly to vulcanization. Everything has a purpose and a responsibility, and each step is essential to achieve a satisfactory result.

During our visit, we also had access to the department responsible for testing and validating that the products or prototypes meet their requirements, performance, and quality standards. They perform all kinds of tests: stress, durability, dimensions, air leak, overpressure, etc. All to guarantee the quality and proper functioning of each product that leaves Hutchinson’s facilities.

Betting on innovation and development

In this sector, as in any other within the cycling industry, being at the forefront of innovation and development is key for Hutchinson, despite the significant effort it entails. Over the years, this investment has translated into a wealth of experience and expertise that supports the brand. It allows it to continue exploring uncharted territory, always striving to stay ahead of the curve.

In this regard, it’s essential to understand that this is by no means an easy task. It involves not only anticipating the demands of cycling in two or three years but also ensuring that your developers’ work aligns with the rest of the market. To give you an idea of what we’re talking about, imagine working for three years on new tires with larger-than-usual dimensions and innovative features, but when you launch the product, the bikes available at that time aren’t designed to accommodate that size. It would be a complete disaster. Hence, the challenge is to continue to innovate while always carefully considering market trends and needs.

We don’t have the whole picture, but we’re sure that with all the buzz surrounding the first mountain bikes with 32-inch wheels, Hutchinson must have been considering adding a new tire diameter for some time.

On the other hand, close collaboration with elite and WorldTour teams, such as Intermarché-Wanty, has always played a significant role in product development, something the brand has greatly valued. Feedback from top-level riders helps them continuously improve their products and achieve peak performance.

Industry and sustainability

Competition is fierce, and despite Hutchinson’s good work and the support it receives from the rest of the group, it often lacks the same budget as other brands or the same visibility. It’s not just about having a good product, but also about effective communication and marketing.

Another crucial aspect, and one in which brands must take responsibility, is the sustainability and recycling of their products. Currently, we know that brands like Hutchinson are making a significant effort to give products that have reached the end of their useful life a second life. In the case of inner tubes, they are already collaborating with external companies to find a solution. As for tires, because the manufacturing process is more complex, using different compounds and materials, addressing this issue is much more difficult. Even so, the brand confirms that it is a matter they are considering and that they hope to find a solution soon.