Being the largest bike producer in Belgium is not an easy task. It means staying true to your roots and at the same time adapting to compete with the international players fighting for the same piece of cake. It requires continuous innovation in a country characterized by its traditional view of cycling.

At Ridley Bikes they can proudly say they have led the Belgian bike frame industry for more than twenty years, and their recently launched models, together with what is to come, are clear evidence that Belgium can count on one of the main entities within the global cycling industry.

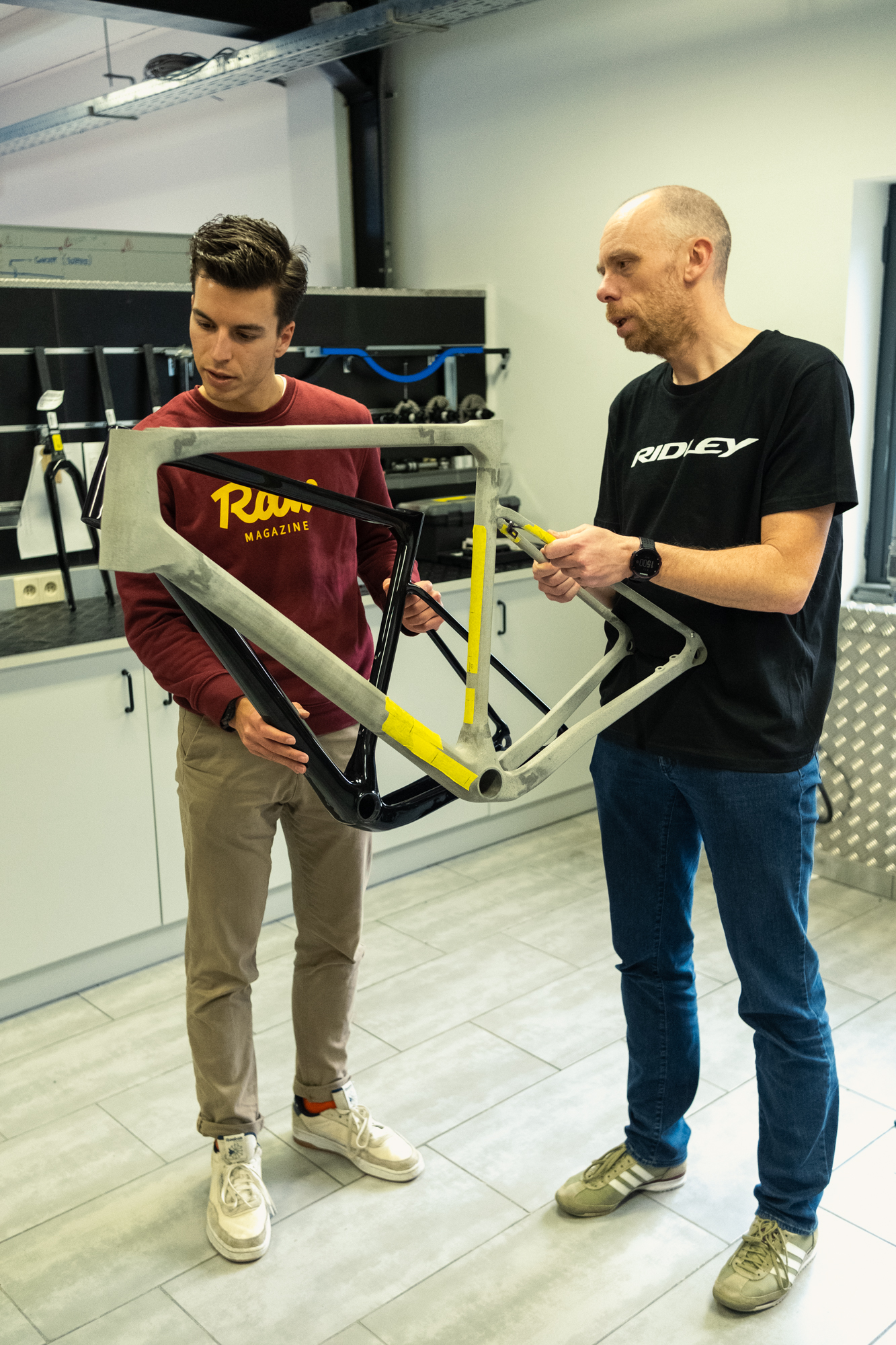

We had the chance to check their headquarters firsthand and we could see why they believe they can achieve their mission. The sense of pride of the CEO when showing their latest innovation in frame painting to us, the excitement of the young Aero Engineer when explaining how the upcoming upgrades of the wind tunnel will put it at the forefront of aero testing… Ridley is a family-owned business, and everyone treats the company like their own child.

Born from an unaccomplished dream

In the last stage of his teenage years, Jochim Aerts realized that his dream of becoming pro was slowly fading away, but he still wanted to be involved with the top level of road cycling. He used to paint his own frames and those of the pros he was in touch with, including his brother. Then he did the same for Bioracer, which at that time was also present in the bike frame business.

He learned about design, geometries, and frame welding, and he stepped up and started taking care of the whole production process of a bike. Ridley was born in 1997, and at that moment he was still based in his father’s garage. In 2005, Ridley bikes were already present at the top level of road racing, with three stage wins at the Tour de France in the first year sponsoring Davitamon – Lotto, the current Lotto Dstny team.

If you wonder where the name of the company comes from, think about the director of films like Alien or Blade Runner, Ridley Scott. At that time the surname of the family’s idol was already taken by another cycling business, so they went for Ridley as the brand’s name.

Towards a local cycling ecosystem

Nowadays, Ridley is the biggest bike producer in Belgium. It is part of Belgian Cycling Factory, a conglomerate that also includes the bike brand Eddy Merckx and other cycling-related companies like Corsa, Forza and BCF Cycling Wear.

In 2013 the Bike Valley, a building first conceived as an innovation center that includes a wind tunnel and heat chamber, was built next to the current Ridley factory. They ran independently for several years but in 2020 the Bike Valley was incorporated into the Ridley business, and since then the combination of the two buildings is called Belgian Cycling Factory (BCF). That also marked the moment in which Jochim Aerts became the sole owner of Ridley. After previously sharing the ownership with other individuals and investment companies, the business went back to its original roots as a family-owned business.

In the factory in Beringen, Belgium, they currently assemble all the bikes for the West European markets. For North American markets, bikes are locally assembled but of course following the same specifications as in the headquarters. The only thing they can decide independently from the headquarters is the colors of the frames, in order to adapt to local trends.

Without major disruptions or unforeseen circumstances, Belgian Cycling Factory should sell 65.000 bikes this year, and taking into account that as of now there is only one shift of people working on the production process, the max capacity of the factory contains six digits.

Several wise decisions were taken during the recent cycling boom, like not trying to meet the excessive demand for bikes knowing that they would not be able to get all the necessary external components to build them. Other brands invested too much and then a missing component put their whole production line on hold.

Since then they are making sure that they do not rely on China and Taiwan in excess. Learning from what happened during the component shortage, aluminum frames of existing models will soon be sourced from The Netherlands, and all the different versions of the two new Ridley models coming up in the next year will be produced in Portugal.

A production process on par with the potential of the brand

After passing by the warehouse, where we saw complete bikes ready to be shipped to Sweden, Poland, or New Zealand, we were explained the whole painting process. Half of the frames are painted in Belgium while the other half is painted in Moldavia.

There is a similar split between paint-personalized bikes and bikes that are sold with the default designs. Many customers are encouraged to select their own colors in the remarkably good configurator given the low extra cost that personalizing Ridley bikes carries when compared to other brands.

The assembly of bikes is divided into two parallel lines. In the past, one operator put together a complete unit, but now there is a moving assembly line in which operators are specialized in a single task that they execute over and over again. Even then, for someone focusing on the drivetrain part, it is not the same to assemble an electronic shifter than a manual shifting group.

Recently, BCF made a big investment in the digitalization of the business processes. For example, the same QR code located in the frame that the end user scans to register the bike warranty was used at an early stage in the Ridley factory to know which parts had to be equipped to it and at any point along the assembly line.

A wide range of products available

Surrounded by frames that some lucky people will soon be riding, we sat down with the Product Manager Bert Kenens to discuss the past, present and future of Ridley and Eddy Merckx.

Ridley introduced its first gravel bike, the X-Trail, already in 2015, so one can say they were ahead of the rest. Four years later they added to the catalogue their first gravel adventure bike, and in 2020 they launched the Kanzo Fast, the first real aero bike in the market. While other bike brands barely had one gravel model available, Ridley already offered all types of off-road dropbars bikes.

“At that moment, everybody was asking us why we needed an aero gravel bike, and today all big brands are developing or have just developed one”

2022 was for Ridley a year of revamping their already varied gravel range, with the new Kanzo Adventure launched at the end of March and the Grifn in December. The latter has just been awarded the Design & Innovation award, which can be considered the Oscars of the cycling industry.

Ridley wants to offer a wide range of products without losing their competitive DNA. They were born as a performance brand and most people associate the company with professional cycling, but they acknowledge the importance of having electric bikes and city bikes at the disposal of their customers. Bert told us that they are working on some e-bike models on the sportive side, which will not be purely branded as Ridley but RES (Ridley E-Speed).

“The goal is to have a similar offering to big American brands like Specialized and Trek. A product portfolio ranging from mountain bikes to commuter bikes with road and gravel in between”

Regarding the bike brand Eddy Merckx, which operates under the Belgian Cycling Factory umbrella since 2017, the positioning is still unclear until the normal production pace of the brand is resumed, but it will aim for a more targeted niche market with no overlap with Ridley. Steel and modern heritage are the two concepts that will probably define the future of the brand.

Not all bike brands have a wind tunnel

We didn’t want to leave without checking the wind tunnel, which had been booked the whole day by an external brand. Ridley is not the exclusive user of the wind tunnel, so all brands and individuals are welcome to test any product. And no, there were no hidden cameras that Ridley could check to see what a possible competitor may be testing there.

Pogacar and Evenepoel have used the tunnel as individuals, and many teams go there to do their tests. There is a new velodrome being built fifteen minutes from the Bike Valley so the combination of wind tunnel testing plus tests on the rack will soon attract even more brands.

There we found Daan Teugels, the young aero engineer who is normally working on the design of new bikes, but who you will probably see on the wind tunnel whenever there are some requests for internal testing. It was a long day for him, but not his longest one. “Dan Bigham was here before his UCI Hour Record and those +10 hour days were exhausting, but also rewarding”, said Daan just before we waved goodbye.

Looking forward to the immediate future

On the one hand, with their historical presence in professional road cycling and cyclocross, together with their first partnership with a top-level MTB team, Ridley is making sure that people identify the brand with performance and competition. On the other hand, their range of adventure bikes and the upcoming electric bikes will allow them to cover the preferences of all types of cycling enthusiasts. The future looks bright for cycling in general, and Belgian Cycling Factory in particular.